Your SlideShare is downloading.

×

×

Saving this for later?

Get the SlideShare app to save on your phone or tablet. Read anywhere, anytime - even offline.

Text the download link to your phone

Standard text messaging rates apply

Like this document? Why not share!

-

Solutions. Design and Analysis of E... by Byron CZ 17380 views

-

Diseño y analisis de experimentos m... by Martin Ramirez Va... 6078 views

-

Design & analysis of experiments (m... by Carlos Calderas L... 1984 views

-

Applied statistics and probability ... by Ankit Katiyar 106540 views

-

Libro analisis y diseño de experime... by Carlos Acosta 80688 views

-

Solution Manual for Applied Statist... by carecacabeludo 7052 views

-

Montgomery applied statistics_proba... by Ankit Katiyar 29201 views

-

Applied statistics and probability ... by carecacabeludo 5112 views

-

Libro analisis y diseño de experime... by karinaflorez 1035 views

-

Design and Analysis of Experiments by Gladys Grace Kikoy 1222 views

-

Introduction to statistical quality... by Armando Morales 7087 views

-

Manual Solution Probability and Sta... by Rahman Hakim 4673 views

Like this? Share it with your network

Share

Solutions from design and analysis o experiments montgomery

97,361

views

views

Published on

Solucionario del libro Diseño y Análisis de experimentos de Douglas Montgomery // Solutions from Montgomery, D.C (2004) Design and Analysis of Experiments, Wiley, NY …

Solucionario del libro Diseño y Análisis de experimentos

de Douglas Montgomery // Solutions from Montgomery, D.C (2004) Design

and Analysis of Experiments, Wiley, NY

Idioma: Inglés

-

Full NameComment goes here.Delete Reply Spam Block

Full NameComment goes here.Delete Reply Spam Block

-

Noorshazzwanee Ahmad at studentsanyonetell me how to download for the chapter 6,7 and 8. there are missingReply

Noorshazzwanee Ahmad at studentsanyonetell me how to download for the chapter 6,7 and 8. there are missingReply -

Marco B. , DECANO FACULTAD DE INGENIERIA MECANICA at UNIVERSIDAD SANTO TOMAS SECCIONAL TUNJAIt´s an excellent help, thank you. Can you tell me where can I find chapters 6, 7 and 8?Reply

Marco B. , DECANO FACULTAD DE INGENIERIA MECANICA at UNIVERSIDAD SANTO TOMAS SECCIONAL TUNJAIt´s an excellent help, thank you. Can you tell me where can I find chapters 6, 7 and 8?Reply -

Salaudeen Shakirudeen at King Fahd University of Petroleum and Mineralsi need the chapters 6, 7 and 8. thanksReply

Salaudeen Shakirudeen at King Fahd University of Petroleum and Mineralsi need the chapters 6, 7 and 8. thanksReply -

Salaudeen Shakirudeen at King Fahd University of Petroleum and Mineralsgood job well done. But chapters 6,7 and 8 are missing. How can we get those chapters?Reply

Salaudeen Shakirudeen at King Fahd University of Petroleum and Mineralsgood job well done. But chapters 6,7 and 8 are missing. How can we get those chapters?Reply -

Juan Villa VargasSabes en donde puedo encontrar las soluciones de los capítulos 6, 7 y 8??Reply

Juan Villa VargasSabes en donde puedo encontrar las soluciones de los capítulos 6, 7 y 8??Reply

Show More

No Downloads

Views

Total Views

97,361

On Slideshare

0

From Embeds

0

Number of Embeds

6

Actions

Shares

91

Downloads

5,510

Comments

11

Likes

21

Embeds

0

No embeds

No notes for slide

Transcript

- 1. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Chapter 2 Simple Comparative Experiments Solutions2-1 The breaking strength of a fiber is required to be at least 150 psi. Past experience has indicated thatthe standard deviation of breaking strength is σ = 3 psi. A random sample of four specimens is tested. Theresults are y1=145, y2=153, y3=150 and y4=147.(a) State the hypotheses that you think should be tested in this experiment. H0: µ = 150 H1: µ > 150(b) Test these hypotheses using α = 0.05. What are your conclusions? n = 4, σ = 3, y = 1/4 (145 + 153 + 150 + 147) = 148.75 y − µo 148.75 − 150 −1.25 zo = = = = −0.8333 σ 3 3 n 4 2 Since z0.05 = 1.645, do not reject.(c) Find the P-value for the test in part (b). From the z-table: P ≅ 1 − [0.7967 + (2 3)(0.7995 − 0.7967 )] = 0.2014(d) Construct a 95 percent confidence interval on the mean breaking strength.The 95% confidence interval is σ σ y − zα 2 ≤ µ ≤ y + zα 2 n n 148.75 − (1.96 )(3 2) ≤ µ ≤ 148.75 + (1.96 )(3 2) 145. 81 ≤ µ ≤ 151. 692-2 The viscosity of a liquid detergent is supposed to average 800 centistokes at 25°C. A randomsample of 16 batches of detergent is collected, and the average viscosity is 812. Suppose we know that thestandard deviation of viscosity is σ = 25 centistokes.(a) State the hypotheses that should be tested. H0: µ = 800 H1: µ ≠ 800(b) Test these hypotheses using α = 0.05. What are your conclusions? 2-1

- 2. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY y − µo 812 − 800 12 Since zα/2 = z0.025 = 1.96, do not reject. zo = = = = 1.92 σ 25 25 n 16 4(c) What is the P-value for the test? P = 2(0.0274) = 0.0549(d) Find a 95 percent confidence interval on the mean. The 95% confidence interval is σ σ y − zα 2 ≤ µ ≤ y + zα 2 n n 812 − (1.96 )(25 4) ≤ µ ≤ 812 + (1.96 )(25 4 ) 812 − 12.25 ≤ µ ≤ 812 + 12.25 799.75 ≤ µ ≤ 824.252-3 The diameters of steel shafts produced by a certain manufacturing process should have a meandiameter of 0.255 inches. The diameter is known to have a standard deviation of σ = 0.0001 inch. Arandom sample of 10 shafts has an average diameter of 0.2545 inches.(a) Set up the appropriate hypotheses on the mean µ. H0: µ = 0.255 H1: µ ≠ 0.255(b) Test these hypotheses using α = 0.05. What are your conclusions? n = 10, σ = 0.0001, y = 0.2545 y − µo 0.2545 − 0.255 zo = = = −15.81 σ 0.0001 n 10Since z0.025 = 1.96, reject H0.(c) Find the P-value for this test. P = 2.6547x10-56(d) Construct a 95 percent confidence interval on the mean shaft diameter. The 95% confidence interval is σ σ y − zα 2 ≤ µ ≤ y + zα 2 n n ⎛ 0.0001 ⎞ ⎛ 0.0001 ⎞ 0.2545 − (1.96 ) ⎜ ⎟ ≤ µ ≤ 0.2545 + (1.96 ) ⎜ ⎟ ⎝ 10 ⎠ ⎝ 10 ⎠ 0. 254438 ≤ µ ≤ 0. 2545622-4 A normally distributed random variable has an unknown mean µ and a known variance σ2 = 9. Findthe sample size required to construct a 95 percent confidence interval on the mean, that has total length of1.0. 2-2

- 3. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Since y ∼ N(µ,9), a 95% two-sided confidence interval on µ is σ σ y − zα 2 ≤ µ ≤ y + zα 2 n n 3 3 y − (196) . ≤ µ ≤ y + (196) . n n If the total interval is to have width 1.0, then the half-interval is 0.5. Since zα/2 = z0.025 = 1.96, (1.96)(3 n ) = 0.5 n = (1.96)(3 0.5) = 11.76 n = (11.76 )2 = 138.30 ≅ 1392-5 The shelf life of a carbonated beverage is of interest. Ten bottles are randomly selected and tested,and the following results are obtained: Days 108 138 124 163 124 159 106 134 115 139(a) We would like to demonstrate that the mean shelf life exceeds 120 days. Set up appropriate hypotheses for investigating this claim. H0: µ = 120 H1: µ > 120(b) Test these hypotheses using α = 0.01. What are your conclusions? y = 131 S2 = 3438 / 9 = 382 S = 382 = 19.54 y − µo 131 − 120 to = = = 1.78 S n 19.54 10 since t0.01,9 = 2.821; do not reject H0Minitab OutputT-Test of the MeanTest of mu = 120.00 vs mu > 120.00Variable N Mean StDev SE Mean T PShelf Life 10 131.00 19.54 6.18 1.78 0.054T Confidence IntervalsVariable N Mean StDev SE Mean 99.0 % CIShelf Life 10 131.00 19.54 6.18 ( 110.91, 151.09) 2-3

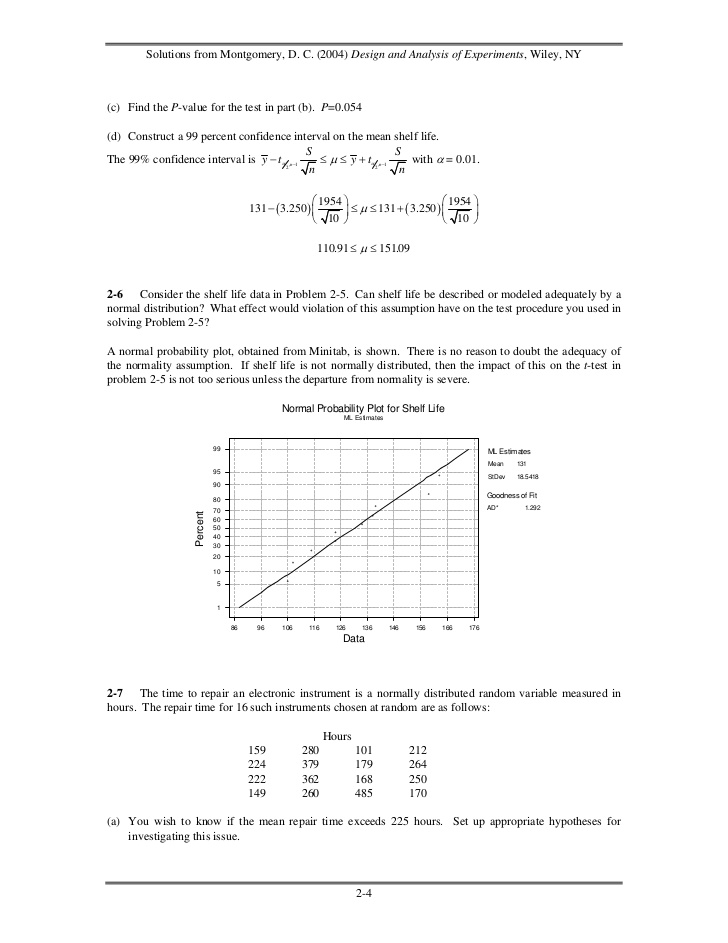

- 4. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY(c) Find the P-value for the test in part (b). P=0.054(d) Construct a 99 percent confidence interval on the mean shelf life. S SThe 99% confidence interval is y − tα 2,n−1 ≤ µ ≤ y + tα 2,n−1 with α = 0.01. n n ⎛ 1954 ⎞ ⎛ 1954 ⎞ 131 − ( 3.250 ) ⎜ ⎟ ≤ µ ≤ 131 + ( 3.250 ) ⎜ ⎟ ⎝ 10 ⎠ ⎝ 10 ⎠ 110.91 ≤ µ ≤ 15109 .2-6 Consider the shelf life data in Problem 2-5. Can shelf life be described or modeled adequately by anormal distribution? What effect would violation of this assumption have on the test procedure you used insolving Problem 2-5?A normal probability plot, obtained from Minitab, is shown. There is no reason to doubt the adequacy ofthe normality assumption. If shelf life is not normally distributed, then the impact of this on the t-test inproblem 2-5 is not too serious unless the departure from normality is severe. Normal Probability Plot for Shelf Life ML Estimates 99 ML Estimates Mean 131 95 StDev 18.5418 90 80 Goodness of Fit 70 AD* 1.292 Percent 60 50 40 30 20 10 5 1 86 96 106 116 126 136 146 156 166 176 Data2-7 The time to repair an electronic instrument is a normally distributed random variable measured inhours. The repair time for 16 such instruments chosen at random are as follows: Hours 159 280 101 212 224 379 179 264 222 362 168 250 149 260 485 170(a) You wish to know if the mean repair time exceeds 225 hours. Set up appropriate hypotheses for investigating this issue. 2-4

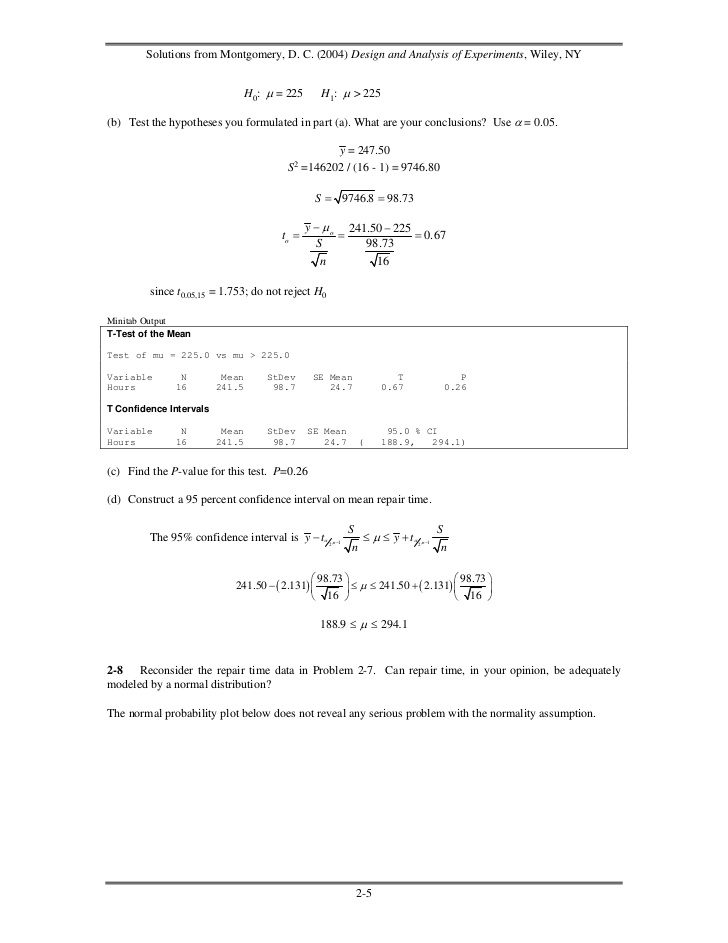

- 5. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY H0: µ = 225 H1: µ > 225(b) Test the hypotheses you formulated in part (a). What are your conclusions? Use α = 0.05. y = 247.50 S2 =146202 / (16 - 1) = 9746.80 S = 9746.8 = 98.73 y − µo 241.50 − 225 to = = = 0.67 S 98.73 n 16 since t0.05,15 = 1.753; do not reject H0Minitab OutputT-Test of the MeanTest of mu = 225.0 vs mu > 225.0Variable N Mean StDev SE Mean T PHours 16 241.5 98.7 24.7 0.67 0.26T Confidence IntervalsVariable N Mean StDev SE Mean 95.0 % CIHours 16 241.5 98.7 24.7 ( 188.9, 294.1)(c) Find the P-value for this test. P=0.26(d) Construct a 95 percent confidence interval on mean repair time. S S The 95% confidence interval is y − tα 2,n−1 ≤ µ ≤ y + tα 2,n−1 n n ⎛ 98.73 ⎞ ⎛ 98.73 ⎞ 241.50 − ( 2.131) ⎜ ⎟ ≤ µ ≤ 241.50 + ( 2.131) ⎜ ⎟ ⎝ 16 ⎠ ⎝ 16 ⎠ 188.9 ≤ µ ≤ 294.12-8 Reconsider the repair time data in Problem 2-7. Can repair time, in your opinion, be adequatelymodeled by a normal distribution?The normal probability plot below does not reveal any serious problem with the normality assumption. 2-5

- 6. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot for Hours ML Estimates 99 ML Estimates Mean 241.5 95 StDev 95.5909 90 80 Goodness of Fit 70 AD* 1.185 Percent 60 50 40 30 20 10 5 1 50 150 250 350 450 Data2-9 Two machines are used for filling plastic bottles with a net volume of 16.0 ounces. The fillingprocesses can be assumed to be normal, with standard deviation of σ1 = 0.015 and σ2 = 0.018. The qualityengineering department suspects that both machines fill to the same net volume, whether or not this volumeis 16.0 ounces. An experiment is performed by taking a random sample from the output of each machine. Machine 1 Machine 2 16.03 16.01 16.02 16.03 16.04 15.96 15.97 16.04 16.05 15.98 15.96 16.02 16.05 16.02 16.01 16.01 16.02 15.99 15.99 16.00(a) State the hypotheses that should be tested in this experiment. H0: µ1 = µ2 H1: µ1 ≠ µ2(b) Test these hypotheses using α=0.05. What are your conclusions? y1 = 16. 015 y2 = 16. 005 σ 1 = 0. 015 σ 2 = 0. 018 n1 = 10 n2 = 10 y1 − y2 16. 015 − 16. 018 zo = = = 1. 35 σ1 2 σ2 0. 0152 0. 0182 + 2 + n1 n2 10 10 z0.025 = 1.96; do not reject(c) What is the P-value for the test? P = 0.1770(d) Find a 95 percent confidence interval on the difference in the mean fill volume for the two machines. 2-6

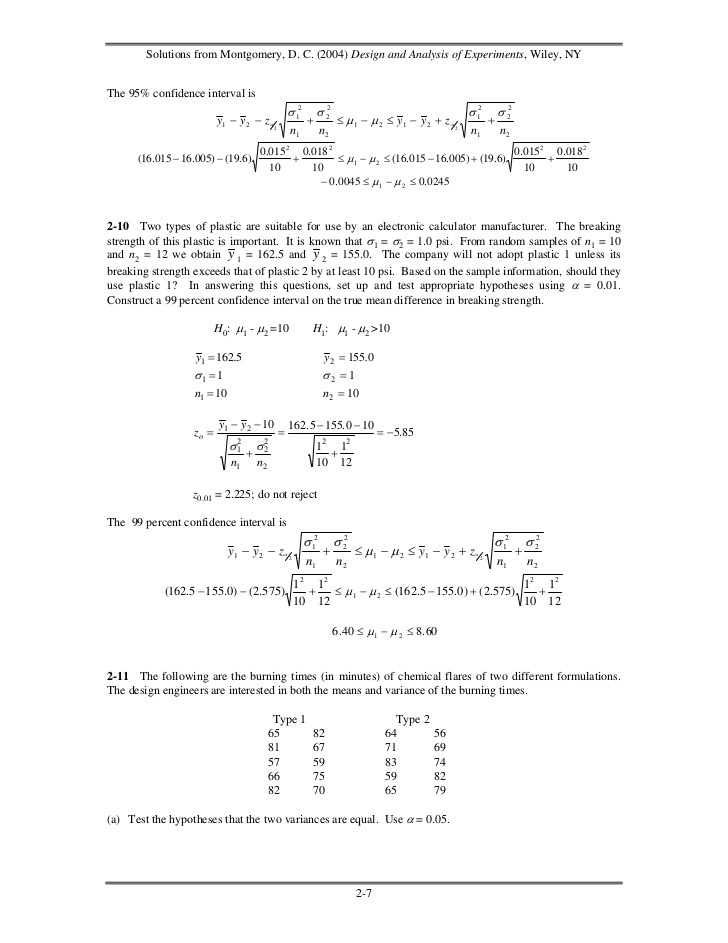

- 7. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYThe 95% confidence interval is σ 12 σ2 2 σ 12 σ2 2 y1 − y 2 − z α 2 + ≤ µ 1 − µ 2 ≤ y1 − y 2 + z α 2 + n1 n2 n1 n2 2 2 0.015 0.018 0.015 2 0.018 2 (16.015 − 16.005) − (19.6) + ≤ µ1 − µ 2 ≤ (16.015 − 16.005) + (19.6) + 10 10 10 10 − 0.0045 ≤ µ 1 − µ 2 ≤ 0.02452-10 Two types of plastic are suitable for use by an electronic calculator manufacturer. The breakingstrength of this plastic is important. It is known that σ1 = σ2 = 1.0 psi. From random samples of n1 = 10and n2 = 12 we obtain y 1 = 162.5 and y 2 = 155.0. The company will not adopt plastic 1 unless itsbreaking strength exceeds that of plastic 2 by at least 10 psi. Based on the sample information, should theyuse plastic 1? In answering this questions, set up and test appropriate hypotheses using α = 0.01.Construct a 99 percent confidence interval on the true mean difference in breaking strength. H0: µ1 - µ2 =10 H1: µ1 - µ2 >10 y1 = 162.5 y2 = 155.0 σ1 = 1 σ2 = 1 n1 = 10 n2 = 10 y1 − y2 − 10 162. 5 − 155. 0 − 10 zo = = = −5.85 σ1 2 σ2 12 12 + 2 + n1 n2 10 12 z0.01 = 2.225; do not rejectThe 99 percent confidence interval is σ 12 σ2 2 σ 12 σ2 2 y1 − y 2 − z α 2 + ≤ µ 1 − µ 2 ≤ y1 − y 2 + z α 2 + n1 n2 n1 n2 12 12 12 12 (162.5 − 155.0) − (2.575) + ≤ µ1 − µ 2 ≤ (162.5 − 155.0) + (2.575) + 10 12 10 12 6.40 ≤ µ 1 − µ 2 ≤ 8.602-11 The following are the burning times (in minutes) of chemical flares of two different formulations.The design engineers are interested in both the means and variance of the burning times. Type 1 Type 2 65 82 64 56 81 67 71 69 57 59 83 74 66 75 59 82 82 70 65 79(a) Test the hypotheses that the two variances are equal. Use α = 0.05. 2-7

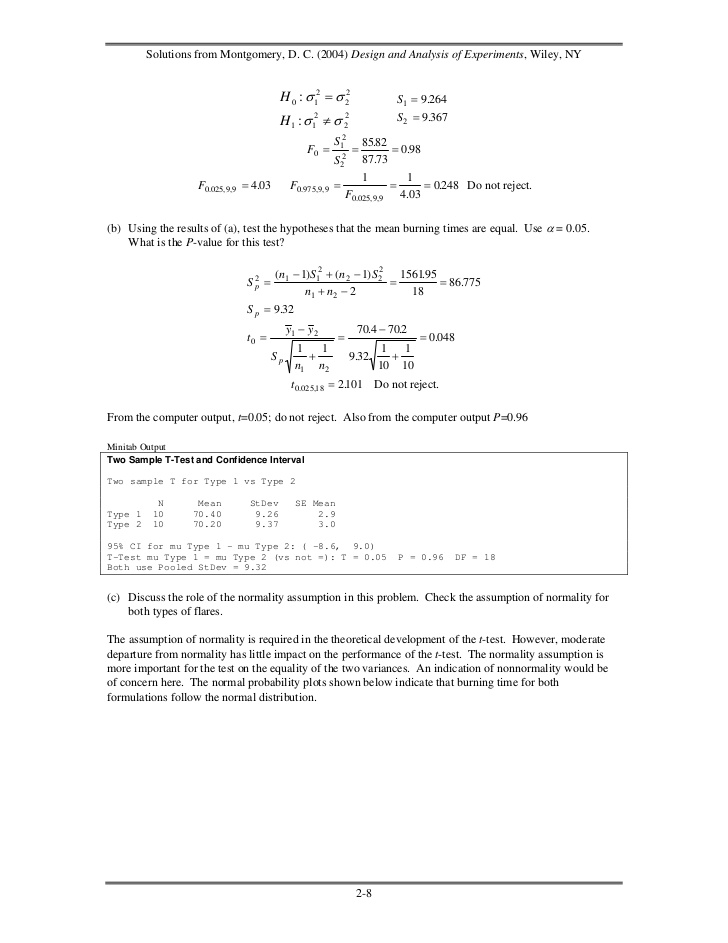

- 8. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY H 0 : σ 12 = σ 2 2 S1 = 9.264 H1 : σ ≠ σ2 2 S 2 = 9.367 1 2 2 S1 8582 . F0 = 2 = = 0.98 S2 87.73 1 1 F0.025,9 ,9 = 4.03 F0.975,9 ,9 = = = 0.248 Do not reject. F0.025,9 ,9 4.03(b) Using the results of (a), test the hypotheses that the mean burning times are equal. Use α = 0.05. What is the P-value for this test? (n1 − 1) S1 + (n 2 − 1) S 2 156195 2 2 . Sp = 2 = = 86.775 n1 + n 2 − 2 18 S p = 9.32 y1 − y 2 70.4 − 70.2 t0 = = = 0.048 1 1 1 1 Sp + 9.32 + n1 n 2 10 10 t 0.025,18 = 2.101 Do not reject.From the computer output, t=0.05; do not reject. Also from the computer output P=0.96Minitab OutputTwo Sample T-Test and Confidence IntervalTwo sample T for Type 1 vs Type 2 N Mean StDev SE MeanType 1 10 70.40 9.26 2.9Type 2 10 70.20 9.37 3.095% CI for mu Type 1 - mu Type 2: ( -8.6, 9.0)T-Test mu Type 1 = mu Type 2 (vs not =): T = 0.05 P = 0.96 DF = 18Both use Pooled StDev = 9.32(c) Discuss the role of the normality assumption in this problem. Check the assumption of normality for both types of flares.The assumption of normality is required in the theoretical development of the t-test. However, moderatedeparture from normality has little impact on the performance of the t-test. The normality assumption ismore important for the test on the equality of the two variances. An indication of nonnormality would beof concern here. The normal probability plots shown below indicate that burning time for bothformulations follow the normal distribution. 2-8

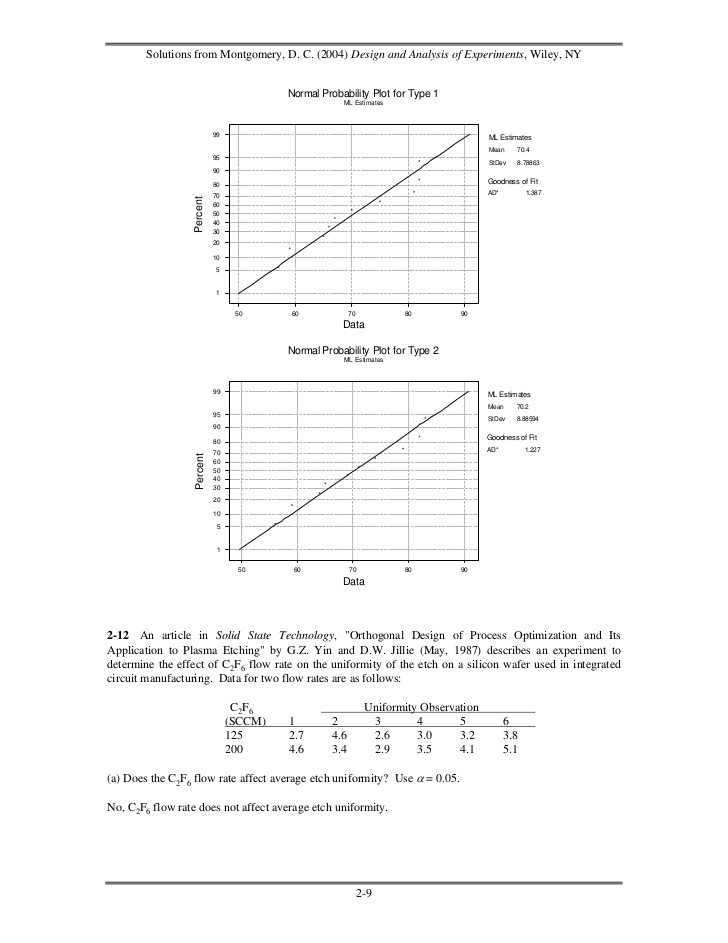

- 9. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot for Type 1 ML Estimates 99 ML Estimates Mean 70.4 95 StDev 8.78863 90 80 Goodness of Fit 70 AD* 1.387 Percent 60 50 40 30 20 10 5 1 50 60 70 80 90 Data Normal Probability Plot for Type 2 ML Estimates 99 ML Estimates Mean 70.2 95 StDev 8.88594 90 80 Goodness of Fit 70 AD* 1.227 Percent 60 50 40 30 20 10 5 1 50 60 70 80 90 Data2-12 An article in Solid State Technology, "Orthogonal Design of Process Optimization and ItsApplication to Plasma Etching" by G.Z. Yin and D.W. Jillie (May, 1987) describes an experiment todetermine the effect of C2F6 flow rate on the uniformity of the etch on a silicon wafer used in integratedcircuit manufacturing. Data for two flow rates are as follows: C2F6 Uniformity Observation (SCCM) 1 2 3 4 5 6 125 2.7 4.6 2.6 3.0 3.2 3.8 200 4.6 3.4 2.9 3.5 4.1 5.1(a) Does the C2F6 flow rate affect average etch uniformity? Use α = 0.05.No, C2F6 flow rate does not affect average etch uniformity. 2-9

- 10. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYMinitab OutputTwo Sample T-Test and Confidence IntervalTwo sample T for UniformityFlow Rat N Mean StDev SE Mean125 6 3.317 0.760 0.31200 6 3.933 0.821 0.3495% CI for mu (125) - mu (200): ( -1.63, 0.40)T-Test mu (125) = mu (200) (vs not =): T = -1.35 P = 0.21 DF = 10Both use Pooled StDev = 0.791(b) What is the P-value for the test in part (a)? From the computer printout, P=0.21(c) Does the C2F6 flow rate affect the wafer-to-wafer variability in etch uniformity? Use α = 0.05. H 0 : σ 12 = σ 2 2 H1 : σ 12 ≠ σ 2 2 F0.05,5,5 = 5.05 0.5776 F0 = = 0.86 0.6724Do not reject; C2F6 flow rate does not affect wafer-to-wafer variability.(d) Draw box plots to assist in the interpretation of the data from this experiment.The box plots shown below indicate that there is little difference in uniformity at the two gas flow rates.Any observed difference is not statistically significant. See the t-test in part (a). 5 Uniformity 4 3 125 200 Flow Rate2-13 A new filtering device is installed in a chemical unit. Before its installation, a random sample 2yielded the following information about the percentage of impurity: y 1 = 12.5, S1 =101.17, and n1 = 8. 2After installation, a random sample yielded y 2 = 10.2, S2 = 94.73, n2 = 9.(a) Can you concluded that the two variances are equal? Use α = 0.05. 2-10

- 11. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY H 0 : σ1 = σ 2 2 2 H1 : σ 1 ≠ σ 2 2 2 F0.025 ,7 ,8 = 4.53 S12 101.17 F0 = 2 = = 1.07 S2 94.73Do Not Reject. Assume that the variances are equal.(b) Has the filtering device reduced the percentage of impurity significantly? Use α = 0.05. H 0 : µ1 = µ 2 H1 : µ1 ≠ µ 2 ( n1 − 1 )S12 + ( n2 − 1 )S 2 ( 8 − 1 )( 101.17 ) + ( 9 − 1 )( 94.73 ) 2 Sp = 2 = = 97.74 n1 + n2 − 2 8+9−2 S p = 9.89 y1 − y2 12.5 − 10.2 t0 = = = 0.479 1 1 1 1 Sp + 9.89 + n1 n2 8 9 t0.05 ,15 = 1.753Do not reject. There is no evidence to indicate that the new filtering device has affected the mean2-14 Photoresist is a light-sensitive material applied to semiconductor wafers so that the circuit patterncan be imaged on to the wafer. After application, the coated wafers are baked to remove the solvent in thephotoresist mixture and to harden the resist. Here are measurements of photoresist thickness (in kÅ) foreight wafers baked at two different temperatures. Assume that all of the runs were made in random order. 95 ºC 100 ºC 11.176 5.263 7.089 6.748 8.097 7.461 11.739 7.015 11.291 8.133 10.759 7.418 6.467 3.772 8.315 8.963(a) Is there evidence to support the claim that the higher baking temperature results in wafers with a lower mean photoresist thickness? Use α = 0.05. 2-11

- 12. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY H 0 : µ1 = µ2 H1 : µ1 ≠ µ2 (n1 − 1) S12 + (n2 − 1) S22 (8 − 1)(4.41) + (8 − 1)(2.54) Sp = 2 = = 3.48 n1 + n2 − 2 8+8−2 S p = 1.86 y1 − y2 9.37 − 6.89 t0 = = = 2.65 1 1 1 1 Sp + 1.86 + n1 n2 8 8 t0.05,14 = 1.761Since t0.05,14 = 1.761, reject H0. There appears to be a lower mean thickness at the higher temperature. Thisis also seen in the computer output.Minitab OutputTwo-Sample T-Test and CI: Thickness, TempTwo-sample T for ThicknessTemp N Mean StDev SE Mean 95 8 9.37 2.10 0.74100 8 6.89 1.60 0.56Difference = mu ( 95) - mu (100)Estimate for difference: 2.47595% CI for difference: (0.476, 4.474)T-Test of difference = 0 (vs not =): T-Value = 2.65 P-Value = 0.019 DF = 14Both use Pooled StDev = 1.86(b) What is the P-value for the test conducted in part (a)? P = 0.019(c) Find a 95% confidence interval on the difference in means. Provide a practical interpretation of this interval.From the computer output the 95% confidence interval is 0.476 ≤ µ1 − µ 2 ≤ 4.474 . This confidence intervaldoesnot include 0 in it, there for there is a difference in the two temperatures on the thickness of the photoresist.(d) Draw dot diagrams to assist in interpreting the results from this experiment. 2-12

- 13. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Dotplot of Thickness vs Temp Temp 95 3.6 4.8 6.0 7.2 8.4 9.6 10.8 12.0 100 Thickness(e) Check the assumption of normality of the photoresist thickness. Normal Probability Plot for Thick@95 ML Estimates - 95% CI 99 ML Estimates Mean 9.36663 95 StDev 1.96396 90 80 Goodness of Fit 70 AD* 1.767 Percent 60 50 40 30 20 10 5 1 5 10 15 Data 2-13

- 14. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot for Thick@100 ML Estimates - 95% CI 99 ML Estimates Mean 6.89163 95 StDev 1.49207 90 80 Goodness of Fit 70 AD* 1.567 Percent 60 50 40 30 20 10 5 1 2 7 12 DataThere are no significant deviations from the normality assumptions.(f) Find the power of this test for detecting an actual difference in means of 2.5 kÅ.Minitab OutputPower and Sample Size2-Sample t TestTesting mean 1 = mean 2 (versus not =)Calculating power for mean 1 = mean 2 + differenceAlpha = 0.05 Sigma = 1.86 SampleDifference Size Power 2.5 8 0.7056(g) What sample size would be necessary to detect an actual difference in means of 1.5 kÅ with a power of at least 0.9?.Minitab OutputPower and Sample Size2-Sample t TestTesting mean 1 = mean 2 (versus not =)Calculating power for mean 1 = mean 2 + differenceAlpha = 0.05 Sigma = 1.86 Sample Target ActualDifference Size Power Power 1.5 34 0.9000 0.9060 2-14

- 15. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYThis result makes intuitive sense. More samples are needed to detect a smaller difference.2-15 Front housings for cell phones are manufactured in an injection molding process. The time the partis allowed to cool in the mold before removal is thought to influence the occurrence of a particularlytroublesome cosmetic defect, flow lines, in the finished housing. After manufacturing, the housings areinspected visually and assigned a score between 1 and 10 based on their appearance, with 10 correspondingto a perfect part and 1 corresponding to a completely defective part. An experiment was conducted usingtwo cool-down times, 10 seconds and 20 seconds, and 20 housings were evaluated at each level of cool-down time. The data are shown below. 10 Seconds 20 Seconds 1 3 7 6 2 6 8 9 1 5 5 5 3 3 9 7 5 2 5 4 1 1 8 6 5 6 6 8 2 8 4 5 3 2 6 8 5 3 7 7(a) Is there evidence to support the claim that the longer cool-down time results in fewer appearance defects? Use α = 0.05.Minitab OutputTwo-Sample T-Test and CI: 10 seconds, 20 secondsTwo-sample T for 10 seconds vs 20 seconds N Mean StDev SE Mean10 secon 20 3.35 2.01 0.4520 secon 20 6.50 1.54 0.34Difference = mu 10 seconds - mu 20 secondsEstimate for difference: -3.15095% CI for difference: (-4.295, -2.005)T-Test of difference = 0 (vs not =): T-Value = -5.57 P-Value = 0.000 DF = 38Both use Pooled StDev = 1.79(b) What is the P-value for the test conducted in part (a)? From the Minitab output, P = 0.000(c) Find a 95% confidence interval on the difference in means. Provide a practical interpretation of this interval.From the computer output, −4.295 ≤ µ1 − µ 2 ≤ −2.005 . This interval does not contain 0. The two samples aredifferent. The 20 second cooling time gives a cosmetically better housing.(d) Draw dot diagrams to assist in interpreting the results from this experiment. 2-15

- 16. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Dotplot of Ranking vs C4 C4 10 sec 20 sec 2 4 6 8 Ranking(e) Check the assumption of normality for the data from this experiment. Normal Probability Plot for 10 seconds ML Estimates - 95% CI 99 ML Estimates Mean 3.35 95 StDev 1.95640 90 80 Goodness of Fit 70 AD* 1.252 Percent 60 50 40 30 20 10 5 1 0 4 8 Data 2-16

- 17. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot for 20 seconds ML Estimates - 95% CI 99 ML Estimates Mean 6.5 95 StDev 1.50000 90 80 Goodness of Fit 70 AD* 0.988 Percent 60 50 40 30 20 10 5 1 2 3 4 5 6 7 8 9 10 11 DataThere are no significant departures from normality.2-16 Twenty observations on etch uniformity on silicon wafers are taken during a qualificationexperiment for a plasma etcher. The data are as follows: 5.34 6.65 4.76 5.98 7.25 6.00 7.55 5.54 5.62 6.21 5.97 7.35 5.44 4.39 4.98 5.25 6.35 4.61 6.00 5.32(a) Construct a 95 percent confidence interval estimate of σ2. ( n − 1) S 2 ≤ σ 2 ≤ ( n − 1) S 2 χα 2 , n −1 2 χ (1−α ), n −1 2 2 ( 20 − 1)( 0.88907 ) ( 20 − 1)( 0.88907 ) 2 2 ≤σ2 ≤ 32.852 8.907 0.457 ≤ σ 2 ≤ 1.686(b) Test the hypothesis that σ2 = 1.0. Use α = 0.05. What are your conclusions? H0 :σ 2 = 1 H1 : σ 2 ≠ 1 SS χ0 = 2 = 15.019 σ0 2 2-17

- 18. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY χ 0.025,19 = 32.852 2 χ 0.975,19 = 8.907 2Do not reject. There is no evidence to indicate that σ 2 ≠ 1(c) Discuss the normality assumption and its role in this problem.The normality assumption is much more important when analyzing variances then when analyzing means.A moderate departure from normality could cause problems with both statistical tests and confidenceintervals. Specifically, it will cause the reported significance levels to be incorrect.(d) Check normality by constructing a normal probability plot. What are your conclusions?The normal probability plot indicates that there is not any serious problem with the normality assumption. Normal Probability Plot for Uniformity ML Estimates 99 ML Estimates Mean 5.828 95 StDev 0.866560 90 80 Goodness of Fit 70 AD* 0.835 Percent 60 50 40 30 20 10 5 1 3.8 4.8 5.8 6.8 7.8 Data2-17 The diameter of a ball bearing was measured by 12 inspectors, each using two different kinds ofcalipers. The results were: Inspector Caliper 1 Caliper 2 Difference Difference^2 1 0.265 0.264 .001 .000001 2 0.265 0.265 .000 0 3 0.266 0.264 .002 .000004 4 0.267 0.266 .001 .000001 5 0.267 0.267 .000 0 6 0.265 0.268 -.003 .000009 7 0.267 0.264 .003 .000009 8 0.267 0.265 .002 .000004 9 0.265 0.265 .000 0 10 0.268 0.267 .001 .000001 11 0.268 0.268 .000 0 12 0.265 0.269 -.004 .000016 ∑ = 0.003 ∑ = 0.000045 2-18

- 19. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY(a) Is there a significant difference between the means of the population of measurements represented by the two samples? Use α = 0.05. H 0 : µ1 = µ 2 H0 : µd = 0 or equivalently H1 : µ 1 ≠ µ 2 H1 : µ d ≠ 0Minitab OutputPaired T-Test and Confidence IntervalPaired T for Caliper 1 - Caliper 2 N Mean StDev SE MeanCaliper 12 0.266250 0.001215 0.000351Caliper 12 0.266000 0.001758 0.000508Difference 12 0.000250 0.002006 0.00057995% CI for mean difference: (-0.001024, 0.001524)T-Test of mean difference = 0 (vs not = 0): T-Value = 0.43 P-Value = 0.674(b) Find the P-value for the test in part (a). P=0.674(c) Construct a 95 percent confidence interval on the difference in the mean diameter measurements for the two types of calipers. Sd S d − tα ≤ µ D ( = µ1 − µ 2 ) ≤ d + tα ,n −1 d , n −1 2 n 2 n 0.002 0.002 0.00025 − 2.201 ≤ µ d ≤ 0.00025 + 2.201 12 12 −0.00102 ≤ µ d ≤ 0.001522-18 An article in the Journal of Strain Analysis (vol.18, no. 2, 1983) compares several procedures forpredicting the shear strength for steel plate girders. Data for nine girders in the form of the ratio ofpredicted to observed load for two of these procedures, the Karlsruhe and Lehigh methods, are as follows: Girder Karlsruhe Method Lehigh Method Difference Difference^2 S1/1 1.186 1.061 0.125 0.015625 S2/1 1.151 0.992 0.159 0.025281 S3/1 1.322 1.063 0.259 0.067081 S4/1 1.339 1.062 0.277 0.076729 S5/1 1.200 1.065 0.135 0.018225 S2/1 1.402 1.178 0.224 0.050176 S2/2 1.365 1.037 0.328 0.107584 S2/3 1.537 1.086 0.451 0.203401 S2/4 1.559 1.052 0.507 0.257049 Sum = 2.465 0.821151 Average = 0.274(a) Is there any evidence to support a claim that there is a difference in mean performance between the two methods? Use α = 0.05. H 0 : µ1 = µ 2 H0 : µd = 0 or equivalently H1 : µ 1 ≠ µ 2 H1 : µ d ≠ 0 2-19

- 20. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY 1 n 1 d= ∑ di = 9 ( 2.465) = 0.274 n i =1 1 ⎡ n 2 1 ⎛ n ⎞2 ⎤ 2 1 ⎢ ∑ di − ⎜ ∑ di ⎟ ⎥ ⎡ 2⎤ 2 1 ⎢ 0.821151 − (2.465) ⎥ n ⎝ i =1 ⎠ ⎥ sd = ⎢ i =1 =⎢ 9 ⎥ = 0.135 ⎢ n −1 ⎥ 9 −1 ⎢ ⎥ ⎢ ⎥ ⎢ ⎥ ⎣ ⎦ ⎣ ⎦ d 0.274 t0 = = = 6.08 Sd 0.135 n 9 t α 2 ,n −1 = t 0.025 ,9 = 2.306 , reject the null hypothesis.Minitab OutputPaired T-Test and Confidence IntervalPaired T for Karlsruhe - Lehigh N Mean StDev SE MeanKarlsruh 9 1.3401 0.1460 0.0487Lehigh 9 1.0662 0.0494 0.0165Difference 9 0.2739 0.1351 0.045095% CI for mean difference: (0.1700, 0.3777)T-Test of mean difference = 0 (vs not = 0): T-Value = 6.08 P-Value = 0.000(b) What is the P-value for the test in part (a)? P=0.0002(c) Construct a 95 percent confidence interval for the difference in mean predicted to observed load. Sd Sd d − tα ,n −1 ≤ µ d ≤ d + tα ,n −1 2 n n 2 0.135 0.135 0.274 − 2.306 ≤ µ d ≤ 0.274 + 2.306 9 9 0.17023 ≤ µ d ≤ 0.37777(d) Investigate the normality assumption for both samples. Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 1.15 1.25 1.35 1.45 1.55 Karlsruhe Av erage: 1.34011 Anderson-Darling Normality Test StDev : 0.146031 A-Squared: 0.286 N: 9 P-Value: 0.537 2-20

- 21. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 1.00 1.05 1.10 1.15 Lehigh Av erage: 1.06622 Anderson-Darling Normality Test StDev : 0.0493806 A-Squared: 0.772 N: 9 P-Value: 0.028(e) Investigate the normality assumption for the difference in ratios for the two methods. Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 0.12 0.22 0.32 0.42 0.52 Difference Av erage: 0.273889 Anderson-Darling Normality Test StDev : 0.135099 A-Squared: 0.318 N: 9 P-Value: 0.464(f) Discuss the role of the normality assumption in the paired t-test.As in any t-test, the assumption of normality is of only moderate importance. In the paired t-test, theassumption of normality applies to the distribution of the differences. That is, the individual samplemeasurements do not have to be normally distributed, only their difference.2-19 The deflection temperature under load for two different formulations of ABS plastic pipe is beingstudied. Two samples of 12 observations each are prepared using each formulation, and the deflectiontemperatures (in °F) are reported below: Formulation 1 Formulation 2 212 199 198 177 176 198 194 213 216 197 185 188 211 191 200 206 200 189 193 195 184 201 197 203 2-21

- 22. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY(a) Construct normal probability plots for both samples. Do these plots support assumptions of normality and equal variance for both samples? Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 185 195 205 215 Form 1 Av erage: 200.5 Anderson-Darling Normality Test StDev : 10.1757 A-Squared: 0.450 N: 12 P-Value: 0.227 Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 175 185 195 205 Form 2 Av erage: 193.083 Anderson-Darling Normality Test StDev : 9.94949 A-Squared: 0.443 N: 12 P-Value: 0.236(b) Do the data support the claim that the mean deflection temperature under load for formulation 1 exceeds that of formulation 2? Use α = 0.05.Minitab OutputTwo Sample T-Test and Confidence IntervalTwo sample T for Form 1 vs Form 2 N Mean StDev SE MeanForm 1 12 200.5 10.2 2.9Form 2 12 193.08 9.95 2.995% CI for mu Form 1 - mu Form 2: ( -1.1, 15.9)T-Test mu Form 1 = mu Form 2 (vs >): T = 1.81 P = 0.042 DF = 22Both use Pooled StDev = 10.1(c) What is the P-value for the test in part (a)? P = 0.042 2-22

- 23. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY2-20 Refer to the data in problem 2-19. Do the data support a claim that the mean deflection temperatureunder load for formulation 1 exceeds that of formulation 2 by at least 3 °F?Yes, formulation 1 exceeds formulation 2 by at least 3 °F.Minitab OutputTwo-Sample T-Test and CI: Form1, Form2Two-sample T for Form1 vs Form2 N Mean StDev SE MeanForm1 12 200.5 10.2 2.9Form2 12 193.08 9.95 2.9rDifference = mu Form1 - mu Form2Estimate for difference: 7.4295% lower bound for difference: 0.36T-Test of difference = 3 (vs >): T-Value = 1.08 P-Value = 0.147 DF = 22Both use Pooled StDev = 10.12-21 In semiconductor manufacturing, wet chemical etching is often used to remove silicon from thebacks of wafers prior to metalization. The etch rate is an important characteristic of this process. Twodifferent etching solutionsare being evaluated. Eight randomly selected wafers have been etched in eachsolution and the observed etch rates (in mils/min) are shown below: Solution 1 Solution 2 9.9 10.6 10.2 10.6 9.4 10.3 10.0 10.2 10.0 9.3 10.7 10.4 10.3 9.8 10.5 10.3(a) Do the data indicate that the claim that both solutions have the same mean etch rate is valid? Use α = 0.05 and assume equal variances.See the Minitab output below.Minitab OutputTwo Sample T-Test and Confidence IntervalTwo sample T for Solution 1 vs Solution 2 N Mean StDev SE MeanSolution 8 9.925 0.465 0.16Solution 8 10.362 0.233 0.08295% CI for mu Solution - mu Solution: ( -0.83, -0.043)T-Test mu Solution = mu Solution (vs not =):T = -2.38 P = 0.032 DF = 14Both use Pooled StDev = 0.368(b) Find a 95% confidence interval on the difference in mean etch rate.From the Minitab output, -0.83 to –0.043.(c) Use normal probability plots to investigate the adequacy of the assumptions of normality and equal variances. 2-23

- 24. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 9.5 10.0 10.5 Solution 1 Av erage: 9.925 Anderson-Darling Normality Test StDev : 0.465219 A-Squared: 0.222 N: 8 P-Value: 0.743 Normal Probability Plot .999 .99 .95 Probability .80 .50 .20 .05 .01 .001 10.0 10.1 10.2 10.3 10.4 10.5 10.6 10.7 Solution 2 Av erage: 10.3625 Anderson-Darling Normality Test StDev : 0.232609 A-Squared: 0.158 N: 8 P-Value: 0.919Both the normality and equality of variance assumptions are valid.2-22 Two popular pain medications are being compared on the basis of the speed of absorption by thebody. Specifically, tablet 1 is claimed to be absorbed twice as fast as tablet 2. Assume that σ 12 and σ 2 2are known. Develop a test statistic for H0: 2µ1 = µ2 H1: 2µ1 ≠ µ2 ⎛ 4σ 2 σ 2 ⎞ 2 y1 − y2 ~ N ⎜ 2 µ1 − µ 2 , 1 + 2 ⎟ , assuming that the data is normally distributed. ⎝ n1 n2 ⎠ 2 y1 − y2 The test statistic is: zo = , reject if zo > zα 2 4 σ1 σ 2 2 + 2 n1 n22-23 Suppose we are testing H0: µ1 = µ2 H1: µ1 ≠ µ2 2-24

- 25. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYwhere σ 12 and σ 2 are known. Our sampling resources are constrained such that n1 + n2 = N. How should 2we allocate the N observations between the two populations to obtain the most powerful test? The most powerful test is attained by the n1 and n2 that maximize zo for given y1 − y2 . Thus, we chose n1 and n2 to y1 − y 2 , subject to n1 + n2 = N. max zo = 2 2 σ1 σ2 + n1 n2 σ1 2 σ2 σ1 2 σ2 This is equivalent to min L = + 2 = + 2 , subject to n1 + n2 = N. n1 n2 n1 N − n1 Now dL = −σ 1 + σ 2 2 2 = 0 , implies that n1 / n2 = σ1 / σ2. ( N − n1 ) 2 2 dn1 n1 Thus n1 and n2 are assigned proportionally to the ratio of the standard deviations. This has intuitive appeal, as it allocates more observations to the population with the greatest variability.2-24 Develop Equation 2-46 for a 100(1 - α) percent confidence interval for the variance of a normaldistribution. SS ~ χ n −1 . Thus, P ⎧ χ 2 ⎨ 2 ≤ SS ⎫ ≤ χ α2 ,n−1 ⎬ = 1 − α . Therefore, σ α σ2 2 ⎩ ⎭ 1− ,n−1 2 2 ⎧ ⎫ ⎪ SS SS ⎪ , P ⎨ 2 ≤ σ 2 ≤ 2 ⎬ = 1−α χ α ,n−1 ⎪ 2 χ1−α ,n−1 ⎪ ⎩ 2 ⎭ ⎡ ⎤ so ⎢ SS , SS ⎥ is the 100(1 - α)% confidence interval on σ2. ⎢ χ α2 ,n−1 χ12−α ,n−1 ⎥ ⎣ 2 2 ⎦2-25 Develop Equation 2-50 for a 100(1 - α) percent confidence interval for the ratio σ 1 / σ 2 , where σ 1 2 2 2and σ 2 are the variances of two normal distributions. 2 S2 σ 2 2 2 ~ Fn2 −1,n1 −1 S12 σ 12 ⎧ S2 σ 2 ⎫ P ⎨ F1−α 2 ,n2 −1,n1 −1 ≤ 2 2 ≤ Fα ⎬ = 1 − α or ⎩ S1 σ 1 2 2 ,n −1,n1−1 2 2 ⎭ ⎧S 2 σ 2 S 2 ⎫ P ⎨ 12 F1−α 2 ,n2 −1,n1 −1 ≤ 12 ≤ 12 Fα ⎬ = 1−α ⎩ S2 σ 2 S2 2 ,n2 −1,n1−1 ⎭2-26 Develop an equation for finding a 100(1 - α) percent confidence interval on the difference in themeans of two normal distributions where σ 12 ≠ σ 2 . Apply your equation to the portland cement 2experiment data, and find a 95% confidence interval. 2-25

- 26. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY ( y1 − y2 ) − ( µ1 − µ2 ) ~ t 2 ,υ α S12 S 2 2 + n1 n2 S12 S2 2 S2 S2 tα 2 ,υ + ≤ ( y1 − y2 ) − ( µ1 − µ 2 ) ≤ tα 2 ,υ 1 + 2 n1 n2 n1 n2 S12 S 2 2 S2 S2 ( y1 − y2 ) − t α 2 ,υ + ≤ ( µ1 − µ 2 ) ≤ ( y1 − y2 ) + tα 2,υ 1 + 2 n1 n2 n1 n2 2 ⎛ S12 S 2 ⎞ 2 ⎜ + ⎟ υ = ⎝ 12 2 ⎠ 2 where n n ⎛ S12 ⎞ ⎛ S 2 ⎞ 2 ⎜ ⎟ ⎜ ⎟ ⎝ n1 ⎠ + ⎝ n2 ⎠ n1 − 1 n2 − 1 Using the data from Table 2-1 n1 = 10 n 2 = 10 y1 = 16.764 y 2 = 17.343 2 S1 = 0100138 . S 2 = 0.0614622 2 0.100138 0.0614622 (16.764 − 17.343) − 2.110 + ≤ ( µ1 − µ 2 ) ≤ 10 10 0.100138 0.0614622 (16.764 − 17.343) + 2.110 + 10 10 2 ⎛ 0.100138 0.0614622 ⎞ ⎜ + ⎟ ⎝ 10 10 ⎠ where υ = 2 2 = 17.024 ≅ 17 ⎛ 0.100138 ⎞ ⎛ 0.0614622 ⎞ ⎜ ⎟ ⎜ ⎟ ⎝ 10 ⎠ ⎝ 10 ⎠ + 10 − 1 10 − 1 −1.426 ≤ ( µ1 − µ2 ) ≤ −0.889This agrees with the result in Table 2-2.2-27 Construct a data set for which the paired t-test statistic is very large, but for which the usual two-sample or pooled t-test statistic is small. In general, describe how you created the data. Does this give youany insight regarding how the paired t-test works? A B delta 7.1662 8.2416 1.07541 2.3590 2.4555 0.09650 19.9977 21.1018 1.10412 0.9077 2.3401 1.43239 -15.9034 -15.0013 0.90204 -6.0722 -5.5941 0.47808 2-26

- 27. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY 9.9501 10.6910 0.74085 -1.0944 -0.1358 0.95854 -4.6907 -3.3446 1.34615 -6.6929 -5.9303 0.76256Minitab OutputPaired T-Test and Confidence IntervalPaired T for A - B N Mean StDev SE MeanA 10 0.59 10.06 3.18B 10 1.48 10.11 3.20Difference 10 -0.890 0.398 0.12695% CI for mean difference: (-1.174, -0.605)T-Test of mean difference = 0 (vs not = 0): T-Value = -7.07 P-Value = 0.000Two Sample T-Test and Confidence IntervalTwo sample T for A vs B N Mean StDev SE MeanA 10 0.6 10.1 3.2B 10 1.5 10.1 3.295% CI for mu A - mu B: ( -10.4, 8.6)T-Test mu A = mu B (vs not =): T = -0.20 P = 0.85 DF = 18Both use Pooled StDev = 10.1These two sets of data were created by making the observation for A and B moderately different withineach pair (or block), but making the observations between pairs very different. The fact that the differencebetween pairs is large makes the pooled estimate of the standard deviation large and the two-sample t-teststatistic small. Therefore the fairly small difference between the means of the two treatments that is presentwhen they are applied to the same experimental unit cannot be detected. Generally, if the blocks are verydifferent, then this will occur. Blocking eliminates the variabiliy associated with the nuisance variable thatthey represent.2-28 Consider the experiment described in problem 2-11. If the mean burning times of the two flamesdiffer by as much as 2 minutes, find the power of the test. What sample size would be required to detect anactual difference in mean burning time of 1 minute with a power of at least 0.90?Minitab OutputPower and Sample Size2-Sample t TestTesting mean 1 = mean 2 (versus not =)Calculating power for mean 1 = mean 2 + differenceAlpha = 0.05 Sigma = 9.32 Sample Target ActualDifference Size Power Power 2 458 0.9000 0.90042-29 Reconsider the bottle filling experiment described in Problem 2-9. Rework this problem assumingthat the two population variances are unknown but equal. 2-27

- 28. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYMinitab OutputTwo-Sample T-Test and CI: Machine 1, Machine 2Two-sample T for Machine 1 vs Machine 2 N Mean StDev SE MeanMachine 10 16.0150 0.0303 0.0096Machine 10 16.0050 0.0255 0.0081Difference = mu Machine 1 - mu Machine 2Estimate for difference: 0.010095% CI for difference: (-0.0163, 0.0363)T-Test of difference = 0 (vs not =): T-Value = 0.80 P-Value = 0.435 DF = 18Both use Pooled StDev = 0.0280The hypothesis test is the same: H0: µ1 = µ2 H1: µ1 ≠ µ2The conclusions are the same as Problem 2-9, do not reject H0. There is no difference in the machines.The P-value for this anlysis is 0.435.The confidence interval is (-0.0163, 0.0363). This interval contains 0. There is no difference in machines.2-29 Consider the data from problem 2-9. If the mean fill volume of the two machines differ by as muchas 0.25 ounces, what is the power of the test used in problem 2-9? What sample size could result in apower of at least 0.9 if the actual difference in mean fill volume is 0.25 ounces?Minitab OutputPower and Sample Size2-Sample t TestTesting mean 1 = mean 2 (versus not =)Calculating power for mean 1 = mean 2 + differenceAlpha = 0.05 Sigma = 0.028 SampleDifference Size Power 0.25 10 1.0000Minitab OutputPower and Sample Size2-Sample t TestTesting mean 1 = mean 2 (versus not =)Calculating power for mean 1 = mean 2 + differenceAlpha = 0.05 Sigma = 0.028 Sample Target ActualDifference Size Power Power 0.25 2 0.9000 0.9805 2-28

- 29. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Chapter 3 Experiments with a Single Factor: The Analysis of Variance Solutions3-1 The tensile strength of portland cement is being studied. Four different mixing techniques can beused economically. The following data have been collected: Mixing Technique Tensile Strength (lb/in2) 1 3129 3000 2865 2890 2 3200 3300 2975 3150 3 2800 2900 2985 3050 4 2600 2700 2600 2765(a) Test the hypothesis that mixing techniques affect the strength of the cement. Use α = 0.05.Design Expert OutputResponse: Tensile Strengthin lb/in^2 ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 4.897E+005 3 1.632E+005 12.73 0.0005 significant A 4.897E+005 3 1.632E+005 12.73 0.0005 Residual 1.539E+005 12 12825.69 Lack of Fit 0.000 0 Pure Error 1.539E+005 12 12825.69 Cor Total 6.436E+005 15 The Model F-value of 12.73 implies the model is significant. There is only a 0.05% chance that a "Model F-Value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) Estimated Standard Mean Error 1-1 2971.00 56.63 2-2 3156.25 56.63 3-3 2933.75 56.63 4-4 2666.25 56.63 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 -185.25 1 80.08 -2.31 0.0392 1 vs 3 37.25 1 80.08 0.47 0.6501 1 vs 4 304.75 1 80.08 3.81 0.0025 2 vs 3 222.50 1 80.08 2.78 0.0167 2 vs 4 490.00 1 80.08 6.12 < 0.0001 3 vs 4 267.50 1 80.08 3.34 0.0059The F-value is 12.73 with a corresponding P-value of .0005. Mixing technique has an effect.(b) Construct a graphical display as described in Section 3-5.3 to compare the mean tensile strengths for the four mixing techniques. What are your conclusions? MS E 12825.7 S yi . = = = 56.625 n 4 3-1

- 30. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY S c a le d t D is t r ib u t io n (4 ) (3 ) (1 ) (2 ) 2700 2800 2900 3000 3100 T e n s ile S t r e n g t hBased on examination of the plot, we would conclude that µ1 and µ3 are the same; that µ 4 differs fromµ1 and µ3 , that µ 2 differs from µ1 and µ3 , and that µ 2 and µ 4 are different.(c) Use the Fisher LSD method with α=0.05 to make comparisons between pairs of means. 2MS E LSD = t α ,N − a n 2 2( 12825.7 ) LSD = t 0.025 ,16 − 4 4 LSD = 2.179 6412.85 = 174.495 Treatment 2 vs. Treatment 4 = 3156.250 - 2666.250 = 490.000 > 174.495 Treatment 2 vs. Treatment 3 = 3156.250 - 2933.750 = 222.500 > 174.495 Treatment 2 vs. Treatment 1 = 3156.250 - 2971.000 = 185.250 > 174.495 Treatment 1 vs. Treatment 4 = 2971.000 - 2666.250 = 304.750 > 174.495 Treatment 1 vs. Treatment 3 = 2971.000 - 2933.750 = 37.250 < 174.495 Treatment 3 vs. Treatment 4 = 2933.750 - 2666.250 = 267.500 > 174.495The Fisher LSD method is also presented in the Design-Expert computer output above. The results agreewith the graphical method for this experiment.(d) Construct a normal probability plot of the residuals. What conclusion would you draw about the validity of the normality assumption?There is nothing unusual about the normal probability plot of residuals. 3-2

- 31. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal plot of residuals 99 95 N orm al % probability 90 80 70 50 30 20 10 5 1 -1 8 1 .2 5 -9 6 .4 3 7 5 -1 1 .6 2 5 7 3 .1 8 7 5 158 R es idual(e) Plot the residuals versus the predicted tensile strength. Comment on the plot.There is nothing unusual about this plot. Residuals vs. Predicted 158 73.1875 Res iduals -11.625 2 -96.4375 -181.25 2666.25 2788.75 2911.25 3033.75 3156.25 Predicted(f) Prepare a scatter plot of the results to aid the interpretation of the results of this experiment.Design-Expert automatically generates the scatter plot. The plot below also shows the sample average foreach treatment and the 95 percent confidence interval on the treatment mean. 3-3

- 32. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY One Factor Plot 3300 3119.75 Tens ile Strength 2939.51 2759.26 2 2579.01 1 2 3 4 Technique3-2 (a) Rework part (b) of Problem 3-1 using Tukey’s test with α = 0.05. Do you get the same conclusions from Tukey’s test that you did from the graphical procedure and/or the Fisher LSD method?Minitab OutputTukeys pairwise comparisons Family error rate = 0.0500Individual error rate = 0.0117Critical value = 4.20Intervals for (column level mean) - (row level mean) 1 2 3 2 -423 53 3 -201 -15 275 460 4 67 252 30 543 728 505No, the conclusions are not the same. The mean of Treatment 4 is different than the means of Treatments1, 2, and 3. However, the mean of Treatment 2 is not different from the means of Treatments 1 and 3according to the Tukey method, they were found to be different using the graphical method and the FisherLSD method.(b) Explain the difference between the Tukey and Fisher procedures.Both Tukey and Fisher utilize a single critical value; however, Tukey’s is based on the studentized rangestatistic while Fisher’s is based on t distribution.3-3 Reconsider the experiment in Problem 3-1. Find a 95 percent confidence interval on the meantensile strength of the portland cement produced by each of the four mixing techniques. Also find a 95 3-4

- 33. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYpercent confidence interval on the difference in means for techniques 1 and 3. Does this aid in interpretingthe results of the experiment? MS E MS E yi . − tα ,N − a ≤ µi ≤ yi . + tα ,N − a 2 n 2 n 1282837 Treatment 1: 2971 ± 2.179 4 2971 ± 123.387 2847.613 ≤ µ1 ≤ 3094.387 Treatment 2: 3156.25±123.387 3032.863 ≤ µ2 ≤ 3279.637 Treatment 3: 2933.75±123.387 2810.363 ≤ µ3 ≤ 3057.137 Treatment 4: 2666.25±123.387 2542.863 ≤ µ 4 ≤ 2789.637 2 MS E 2MS E Treatment 1 - Treatment 3: yi . − y j . − tα ,N − a ≤ µi − µ j ≤ yi . − y j . + tα ,N − a 2 n 2 n 2(12825.7 ) 2971.00 − 2933.75 ± 2.179 4 −137.245 ≤ µ1 − µ3 ≤ 211.7453-4 A product developer is investigating the tensile strength of a new synthetic fiber that will be used tomake cloth for men’s shirts. Strength is usually affected by the percentage of cotton used in the blend ofmaterials for the fiber. The engineer conducts an experiment with five levels of cotton content andreplicated the experiment five times. The data are shown in the following table. Cotton Observations Weight Percentage 15 7 7 15 11 9 20 12 17 12 18 18 25 14 19 19 18 18 30 19 25 22 19 23 35 7 10 11 15 11(a) Is there evidence to support the claim that cotton content affects the mean tensile strength? Use α = 0.05.Minitab OutputOne-way ANOVA: Tensile Strength versus Cotton PercentageAnalysis of Variance for TensileSource DF SS MS F PCotton P 4 475.76 118.94 14.76 0.000Error 20 161.20 8.06Total 24 636.96Yes, the F-value is 14.76 with a corresponding P-value of 0.000. The percentage of cotton in the fiberappears to have an affect on the tensile strength. 3-5

- 34. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY(b) Use the Fisher LSD method to make comparisons between the pairs of means. What conclusions can you draw?Minitab OutputFishers pairwise comparisons Family error rate = 0.264Individual error rate = 0.0500Critical value = 2.086Intervals for (column level mean) - (row level mean) 15 20 25 30 20 -9.346 -1.854 25 -11.546 -5.946 -4.054 1.546 30 -15.546 -9.946 -7.746 -8.054 -2.454 -0.254 35 -4.746 0.854 3.054 7.054 2.746 8.346 10.546 14.546In the Minitab output the pairs of treatments that do not contain zero in the pair of numbers indicates thatthere is a difference in the pairs of the treatments. 15% cotton is different than 20%, 25% and 30%. 20%cotton is different than 30% and 35% cotton. 25% cotton is different than 30% and 35% cotton. 30%cotton is different than 35%.(c) Analyze the residuals from this experiment and comment on model adequacy. Normal Probability Plot of the Residuals (response is Tensile) 2 1 Normal Score 0 -1 -2 -4 -3 -2 -1 0 1 2 3 4 5 6 Residual 3-6

- 35. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Residuals Versus the Fitted Values (response is Tensile) 6 5 4 3 2 Residual 1 0 -1 -2 -3 -4 10 15 20 Fitted ValueThe residuals show nothing unusual.3-5 Reconsider the experiment described in Problem 3-4. Suppose that 30 percent cotton content is acontrol. Use Dunnett’s test with α = 0.05 to compare all of the other means with the control.For this problem: a = 5, a-1 = 4, f=20, n=5 and α = 0.05 2 MS E 2(8.06) d 0.05 (4, 20) = 2.65 = 4.76 n n 1 vs. 4 : y1. − y4. = 9.8 − 21.6 = −11.8* 2 vs. 4 : y2. − y4. = 15.4 − 21.6 = −6.2 * 3 vs. 4 : y3. − y4. = 17.6 − 21.6 = −4.0 5 vs. 4 : y5. − y4. = 10.8 − 21.6 = −10.6 *The control treatment, treatment 4, differs from treatments 1,2 and 5.3-6 A pharmaceutical manufacturer wants to investigate the bioactivity of a new drug. A completelyrandomized single-factor experiment was conducted with three dosage levels, and the following resultswere obtained. Dosage Observations 20g 24 28 37 30 30g 37 44 31 35 3-7

- 36. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY 40g 42 47 52 38(a) Is there evidence to indicate that dosage level affects bioactivity? Use α = 0.05.Minitab OutputOne-way ANOVA: Activity versus DosageAnalysis of Variance for ActivitySource DF SS MS F PDosage 2 450.7 225.3 7.04 0.014Error 9 288.3 32.0Total 11 738.9There appears to be a different in the dosages.(b) If it is appropriate to do so, make comparisons between the pairs of means. What conclusions can youdraw?Because there appears to be a difference in the dosages, the comparison of means is appropriate.Minitab OutputTukeys pairwise comparisons Family error rate = 0.0500Individual error rate = 0.0209Critical value = 3.95Intervals for (column level mean) - (row level mean) 20g 30g 30g -18.177 4.177 40g -26.177 -19.177 -3.823 3.177The Tukey comparison shows a difference in the means between the 20g and the 40g dosages.(c) Analyze the residuals from this experiment and comment on the model adequacy. 3-8

- 37. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal Probability Plot of the Residuals (response is Activity) 1 Normal Score 0 -1 -2 -5 0 5 Residual Residuals Versus the Fitted Values (response is Activity) 5 Residual 0 -5 30 35 40 45 Fitted ValueThere is nothing too unusual about the residuals.3-7 A rental car company wants to investigate whether the type of car rented affects the length of therental period. An experiment is run for one week at a particular location, and 10 rental contracts areselected at random for each car type. The results are shown in the following table. 3-9

- 38. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Type of Car Observations Sub-compact 3 5 3 7 6 5 3 2 1 6 Compact 1 3 4 7 5 6 3 2 1 7 Midsize 4 1 3 5 7 1 2 4 2 7 Full Size 3 5 7 5 10 3 4 7 2 7(a) Is there evidence to support a claim that the type of car rented affects the length of the rental contract?Use α = 0.05. If so, which types of cars are responsible for the difference?Minitab OutputOne-way ANOVA: Days versus Car TypeAnalysis of Variance for DaysSource DF SS MS F PCar Type 3 16.68 5.56 1.11 0.358Error 36 180.30 5.01Total 39 196.98There is no difference.(b) Analyze the residuals from this experiment and comment on the model adequacy. Normal Probability Plot of the Residuals (response is Days) 2 1 Normal Score 0 -1 -2 -4 -3 -2 -1 0 1 2 3 4 5 Residual 3-10

- 39. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Residuals Versus the Fitted Values (response is Days) 5 4 3 2 Residual 1 0 -1 -2 -3 -4 3.5 4.5 5.5 Fitted ValueThere is nothing unusual about the residuals.(c) Notice that the response variable in this experiment is a count. Should the cause any potential concernsabout the validity of the analysis of variance?Because the data is count data, a square root transformation could be applied. The analysis is shownbelow. It does not change the interpretation of the data.Minitab OutputOne-way ANOVA: Sqrt Days versus Car TypeAnalysis of Variance for Sqrt DaySource DF SS MS F PCar Type 3 1.087 0.362 1.10 0.360Error 36 11.807 0.328Total 39 12.8933-8 I belong to a golf club in my neighborhood. I divide the year into three golf seasons: summer (June-September), winter (November-March) and shoulder (October, April and May). I believe that I play mybest golf during the summer (because I have more time and the course isn’t crowded) and shoulder(because the course isn’t crowded) seasons, and my worst golf during the winter (because all of the part-year residents show up, and the course is crowded, play is slow, and I get frustrated). Data from the lastyear are shown in the following table. Season Observations Summer 83 85 85 87 90 88 88 84 91 90 Shoulde r 91 87 84 87 85 86 83 Winter 94 91 87 85 87 91 92 86 3-11

- 40. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY(a) Do the data indicate that my opinion is correct? Use α = 0.05.Minitab OutputOne-way ANOVA: Score versus SeasonAnalysis of Variance for ScoreSource DF SS MS F PSeason 2 35.61 17.80 2.12 0.144Error 22 184.63 8.39Total 24 220.24The data do not support the author’s opinion.(b) Analyze the residuals from this experiment and comment on model adequacy. Normal Probability Plot of the Residuals (response is Score) 2 1 Normal Score 0 -1 -2 -4 -3 -2 -1 0 1 2 3 4 5 Residual 3-12

- 41. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Residuals Versus the Fitted Values (response is Score) 5 4 3 2 Residual 1 0 -1 -2 -3 -4 86 87 88 89 Fitted ValueThere is nothing unusual about the residuals.3-9 A regional opera company has tried three approaches to solicit donations from 24 potential sponsors.The 24 potential sponsors were randomly divided into three groups of eight, and one approach was usedfor each group. The dollar amounts of the resulting contributions are shown in the following table. Approac h Contributions (in $) 1 1000 1500 1200 1800 1600 1100 1000 1250 2 1500 1800 2000 1200 2000 1700 1800 1900 3 900 1000 1200 1500 1200 1550 1000 1100(a) Do the data indicate that there is a difference in results obtained from the three different approaches?Use α = 0.05.Minitab OutputOne-way ANOVA: Contribution versus ApproachAnalysis of Variance for ContributionSource DF SS MS F PApproach 2 1362708 681354 9.41 0.001Error 21 1520625 72411Total 23 2883333There is a difference between the approaches. The Tukey test will indicate which are different. Approach2 is different than approach 3.Minitab OutputTukeys pairwise comparisons Family error rate = 0.0500Individual error rate = 0.0200Critical value = 3.56 3-13

- 42. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYIntervals for (column level mean) - (row level mean) 1 2 2 -770 -93 3 -214 218 464 895(b) Analyze the residuals from this experiment and comment on the model adequacy. Normal Probability Plot of the Residuals (response is Contribu) 2 1 Normal Score 0 -1 -2 -500 0 500 Residual 3-14

- 43. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Residuals Versus the Fitted Values (response is Contribu) 500 Residual 0 -500 1150 1250 1350 1450 1550 1650 1750 Fitted ValueThere is nothing unusual about the residuals.3-10 An experiment was run to determine whether four specific firing temperatures affect the density of acertain type of brick. The experiment led to the following data: Temperature Density 100 21.8 21.9 21.7 21.6 21.7 125 21.7 21.4 21.5 21.4 150 21.9 21.8 21.8 21.6 21.5 175 21.9 21.7 21.8 21.4(a) Does the firing temperature affect the density of the bricks? Use α = 0.05.No, firing temperature does not affect the density of the bricks. Refer to the Design-Expert output below.Design Expert Output Response: Density ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 0.16 3 0.052 2.02 0.1569 not significant A 0.16 3 0.052 2.02 0.1569 Residual 0.36 14 0.026 Lack of Fit 0.000 0 Pure Error 0.36 14 0.026 Cor Total 0.52 17 The "Model F-value" of 2.02 implies the model is not significant relative to the noise. There is a 15.69 % chance that a "Model F-value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) 3-15

- 44. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Estimated Standard Mean Error 1-100 21.74 0.072 2-125 21.50 0.080 3-150 21.72 0.072 4-175 21.70 0.080 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 0.24 1 0.11 2.23 0.0425 1 vs 3 0.020 1 0.10 0.20 0.8465 1 vs 4 0.040 1 0.11 0.37 0.7156 2 vs 3 -0.22 1 0.11 -2.05 0.0601 2 vs 4 -0.20 1 0.11 -1.76 0.0996 3 vs 4 0.020 1 0.11 0.19 0.8552(b) Is it appropriate to compare the means using the Fisher LSD method in this experiment?The analysis of variance tells us that there is no difference in the treatments. There is no need to proceedwith Fisher’s LSD method to decide which mean is difference.(c) Analyze the residuals from this experiment. Are the analysis of variance assumptions satisfied? There is nothing unusual about the residual plots. Normal plot of residuals Residuals vs. Predicted 0.2 99 95 0.075 2 Norm al % probability 90 80 Res iduals 70 50 -0.05 2 30 2 20 10 -0.175 5 1 -0.3 -0.3 -0.175 -0.05 0.075 0.2 21.50 21.56 21.62 21.68 21.74 Res idual Predicted(d) Construct a graphical display of the treatments as described in Section 3-5.3. Does this graph adequately summarize the results of the analysis of variance in part (b). Yes. 3-16

- 45. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY S c a le d t D is tr ib u tio n (1 2 5 ) (1 7 5 ,1 5 0 ,1 0 0 ) 2 1 .2 2 1 .3 2 1 .4 2 1 .5 2 1 .6 2 1 .7 2 1 .8 M e a n D e n s ity3-11 Rework Part (d) of Problem 3-10 using the Tukey method. What conclusions can you draw?Explain carefully how you modified the procedure to account for unequal sample sizes. When sample sizes are unequal, the appropriate formula for the Tukey method is qα (a, f ) ⎛1 1⎞ Tα = MS E ⎜ + ⎟ ⎜n n ⎟ 2 ⎝ i j ⎠ Treatment 1 vs. Treatment 2 = 21.74 – 21.50 = 0.24 < 0.994 Treatment 1 vs. Treatment 3 = 21.74 – 21.72 = 0.02 < 0.937 Treatment 1 vs. Treatment 4 = 21.74 – 21.70 = 0.04 < 0.994 Treatment 3 vs. Treatment 2 = 21.72 – 21.50 = 0.22 < 1.048 Treatment 4 vs. Treatment 2 = 21.70 – 21.50 = 0.20 < 1.048 Treatment 3 vs. Treatment 4 = 21.72 – 21.70 = 0.02 < 0.994All pairwise comparisons do not identify differences. Notice that there are different critical values for thecomparisons depending on the sample sizes of the two groups being compared.Because we could not reject the hypothesis of equal means using the analysis of variance, we should neverhave performed the Tukey test (or any other multiple comparison procedure, for that matter). If you ignorethe analysis of variance results and run multiple comparisons, you will likely make type I errors.3-12 A manufacturer of television sets is interested in the effect of tube conductivity of four differenttypes of coating for color picture tubes. The following conductivity data are obtained: Coating Type Conductivity 1 143 141 150 146 2 152 149 137 143 3 134 136 132 127 4 129 127 132 129(a) Is there a difference in conductivity due to coating type? Use α = 0.05.Yes, there is a difference in means. Refer to the Design-Expert output below.. 3-17

- 46. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYDesign Expert Output ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 844.69 3 281.56 14.30 0.0003 significant A 844.69 3 281.56 14.30 0.0003 Residual 236.25 12 19.69 Lack of Fit 0.000 0 Pure Error 236.25 12 19.69 Cor Total 1080.94 15 The Model F-value of 14.30 implies the model is significant. There is only a 0.03% chance that a "Model F-Value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) Estimated Standard Mean Error 1-1 145.00 2.22 2-2 145.25 2.22 3-3 132.25 2.22 4-4 129.25 2.22 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 -0.25 1 3.14 -0.080 0.9378 1 vs 3 12.75 1 3.14 4.06 0.0016 1 vs 4 15.75 1 3.14 5.02 0.0003 2 vs 3 13.00 1 3.14 4.14 0.0014 2 vs 4 16.00 1 3.14 5.10 0.0003 3 vs 4 3.00 1 3.14 0.96 0.3578(b) Estimate the overall mean and the treatment effects. µ = 2207 / 16 = 137.9375 ˆ τ 1 = y1. − y .. = 145.00 − 137.9375 = 7.0625 ˆ τ 2 = y 2. − y .. = 145.25 − 137.9375 = 7.3125 ˆ τ 3 = y 3. − y .. = 132.25 − 137.9375 = −5.6875 ˆ τ 4 = y 4. − y .. = 129.25 − 137.9375 = −8.6875 ˆ(c) Compute a 95 percent interval estimate of the mean of coating type 4. Compute a 99 percent interval estimate of the mean difference between coating types 1 and 4. 19.69 Treatment 4: 129.25 ± 2.179 4 124.4155 ≤ µ 4 ≤ 134.0845 Treatment 1 - Treatment 4: (145 − 129.25) ± 3.055 (2)19.69 4 6.164 ≤ µ1 − µ4 ≤ 25.336(d) Test all pairs of means using the Fisher LSD method with α=0.05.Refer to the Design-Expert output above. The Fisher LSD procedure is automatically included in theoutput. 3-18

- 47. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYThe means of Coating Type 2 and Coating Type 1 are not different. The means of Coating Type 3 andCoating Type 4 are not different. However, Coating Types 1 and 2 produce higher mean conductivity thatdoes Coating Types 3 and 4.(e) Use the graphical method discussed in Section 3-5.3 to compare the means. Which coating produces the highest conductivity? MS E 16.96 S yi . = = = 2.219 Coating types 1 and 2 produce the highest conductivity. n 4 S c a le d t D is t r ib u t io n (4 ) (3 ) (1 )(2 ) 130 135 140 145 150 C o n d u c t iv it y(f) Assuming that coating type 4 is currently in use, what are your recommendations to the manufacturer? We wish to minimize conductivity.Since coatings 3 and 4 do not differ, and as they both produce the lowest mean values of conductivity, useeither coating 3 or 4. As type 4 is currently being used, there is probably no need to change.3-13 Reconsider the experiment in Problem 3-12. Analyze the residuals and draw conclusions aboutmodel adequacy.There is nothing unusual in the normal probability plot. A funnel shape is seen in the plot of residualsversus predicted conductivity indicating a possible non-constant variance. 3-19

- 48. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal plot of residuals Residuals vs. Predicted 6.75 99 95 3 Norm al % probability 90 80 Res iduals 70 2 50 -0.75 30 20 10 -4.5 5 1 -8.25 -8.25 -4.5 -0.75 3 6.75 129.25 133.25 137.25 141.25 145.25 Res idual Predicted Residuals vs. Coating Type 6.75 3 Res iduals 2 -0.75 -4.5 -8.25 1 2 3 4 Coating Type3-14 An article in the ACI Materials Journal (Vol. 84, 1987. pp. 213-216) describes several experimentsinvestigating the rodding of concrete to remove entrapped air. A 3” x 6” cylinder was used, and thenumber of times this rod was used is the design variable. The resulting compressive strength of theconcrete specimen is the response. The data are shown in the following table. Rodding Level Compressive Strength 10 1530 1530 1440 15 1610 1650 1500 20 1560 1730 1530 25 1500 1490 1510(a) Is there any difference in compressive strength due to the rodding level? Use α = 0.05.There are no differences.Design Expert Output 3-20

- 49. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 28633.33 3 9544.44 1.87 0.2138 not significant A 28633.33 3 9544.44 1.87 0.2138 Residual 40933.33 8 5116.67 Lack of Fit 0.000 0 Pure Error 40933.33 8 5116.67 Cor Total 69566.67 11 The "Model F-value" of 1.87 implies the model is not significant relative to the noise. There is a 21.38 % chance that a "Model F-value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) Estimated Standard Mean Error 1-10 1500.00 41.30 2-15 1586.67 41.30 3-20 1606.67 41.30 4-25 1500.00 41.30 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 -86.67 1 58.40 -1.48 0.1761 1 vs 3 -106.67 1 58.40 -1.83 0.1052 1 vs 4 0.000 1 58.40 0.000 1.0000 2 vs 3 -20.00 1 58.40 -0.34 0.7408 2 vs 4 86.67 1 58.40 1.48 0.1761 3 vs 4 106.67 1 58.40 1.83 0.1052(b) Find the P-value for the F statistic in part (a). From computer output, P=0.2138.(c) Analyze the residuals from this experiment. What conclusions can you draw about the underlying model assumptions?There is nothing unusual about the residual plots. Normal plot of residuals Residuals vs. Predicted 123.333 99 95 70.8333 Norm al % probability 90 80 Res iduals 70 2 50 18.3333 30 20 10 -34.1667 5 1 -86.6667 -86.6667 -34.1667 18.3333 70.8333 123.333 1500.00 1526.67 1553.33 1580.00 1606.67 Res idual Predicted 3-21

- 50. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Residuals vs. Rodding Level 123.333 70.8333 Res iduals 2 18.3333 -34.1667 -86.6667 1 2 3 4 Rodding Level(d) Construct a graphical display to compare the treatment means as describe in Section 3-5.3. S c a le d t D is tr ib u tio n (1 0 , 2 5 ) (1 5 ) (2 0 ) 1418 1459 1500 1541 1582 1623 1664 M e a n C o m p r e s s iv e S tr e n g th3-15 An article in Environment International (Vol. 18, No. 4, 1992) describes an experiment in which theamount of radon released in showers was investigated. Radon enriched water was used in the experimentand six different orifice diameters were tested in shower heads. The data from the experiment are shown inthe following table. Orifice Dia. Radon Released (%) 0.37 80 83 83 85 0.51 75 75 79 79 0.71 74 73 76 77 1.02 67 72 74 74 1.40 62 62 67 69 1.99 60 61 64 66(a) Does the size of the orifice affect the mean percentage of radon released? Use α = 0.05. 3-22

- 51. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NYYes. There is at least one treatment mean that is different.Design Expert Output Response: Radon Released in % ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 1133.38 5 226.68 30.85 < 0.0001 significant A 1133.38 5 226.68 30.85 < 0.0001 Residual 132.25 18 7.35 Lack of Fit 0.000 0 Pure Error 132.25 18 7.35 Cor Total 1265.63 23 The Model F-value of 30.85 implies the model is significant. There is only a 0.01% chance that a "Model F-Value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) EstimatedStandard Mean Error 1-0.37 82.75 1.36 2-0.51 77.00 1.36 3-0.71 75.00 1.36 4-1.02 71.75 1.36 5-1.40 65.00 1.36 6-1.99 62.75 1.36 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 5.75 1 1.92 3.00 0.0077 1 vs 3 7.75 1 1.92 4.04 0.0008 1 vs 4 11.00 1 1.92 5.74 < 0.0001 1 vs 5 17.75 1 1.92 9.26 < 0.0001 1 vs 6 20.00 1 1.92 10.43 < 0.0001 2 vs 3 2.00 1 1.92 1.04 0.3105 2 vs 4 5.25 1 1.92 2.74 0.0135 2 vs 5 12.00 1 1.92 6.26 < 0.0001 2 vs 6 14.25 1 1.92 7.43 < 0.0001 3 vs 4 3.25 1 1.92 1.70 0.1072 3 vs 5 10.00 1 1.92 5.22 < 0.0001 3 vs 6 12.25 1 1.92 6.39 < 0.0001 4 vs 5 6.75 1 1.92 3.52 0.0024 4 vs 6 9.00 1 1.92 4.70 0.0002 5 vs 6 2.25 1 1.92 1.17 0.2557(b) Find the P-value for the F statistic in part (a). P=3.161 x 10-8(c) Analyze the residuals from this experiment.There is nothing unusual about the residuals. 3-23

- 52. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal plot of residuals Residuals vs. Predicted 4 99 95 2 2 1.8125 Norm al % probability 90 80 Res iduals 70 2 50 -0.375 30 20 2 10 -2.5625 5 2 1 -4.75 -4.75 -2.5625 -0.375 1.8125 4 62.75 67.75 72.75 77.75 82.75 Res idual Predicted Residuals vs. Orifice Diameter 4 2 2 1.8125 Res iduals 2 -0.375 2 -2.5625 2 -4.75 1 2 3 4 5 6 Orifice Diam eter(d) Find a 95 percent confidence interval on the mean percent radon released when the orifice diameter is 1.40. 7.35 Treatment 5 (Orifice =1.40): 6 ± 2.101 4 62.152 ≤ µ ≤ 67.848(e) Construct a graphical display to compare the treatment means as describe in Section 3-5.3. What conclusions can you draw? 3-24

- 53. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY S c a le d t D is t r ib u t io n (6 ) (5 ) (4 ) (3 ) (2 ) (1 ) 60 65 70 75 80 C o n d u c t iv it yTreatments 5 and 6 as a group differ from the other means; 2, 3, and 4 as a group differ from the othermeans, 1 differs from the others.3-16 The response time in milliseconds was determined for three different types of circuits that could beused in an automatic valve shutoff mechanism. The results are shown in the following table. Circuit Type Response Time 1 9 12 10 8 15 2 20 21 23 17 30 3 6 5 8 16 7(a) Test the hypothesis that the three circuit types have the same response time. Use α = 0.01.From the computer printout, F=16.08, so there is at least one circuit type that is different.Design Expert Output Response: Response Time in ms ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 543.60 2 271.80 16.08 0.0004 significant A 543.60 2 271.80 16.08 0.0004 Residual 202.80 12 16.90 Lack of Fit 0.000 0 Pure Error 202.80 12 16.90 Cor Total 746.40 14 The Model F-value of 16.08 implies the model is significant. There is only a 0.04% chance that a "Model F-Value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) Estimated Standard Mean Error 1-1 10.80 1.84 2-2 22.20 1.84 3-3 8.40 1.84 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 3-25

- 54. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY 1 vs 2 -11.40 1 2.60 -4.38 0.0009 1 vs 3 2.40 1 2.60 0.92 0.3742 2 vs 3 13.80 1 2.60 5.31 0.0002(b) Use Tukey’s test to compare pairs of treatment means. Use α = 0.01. MS E 1690 S yi . = = = 1.8385 n 5 q0.01,(3,12 ) = 5.04 t0 = 1.8385(5.04) = 9.266 1 vs. 2: ⏐10.8-22.2⏐=11.4 > 9.266 1 vs. 3: ⏐10.8-8.4⏐=2.4 < 9.266 2 vs. 3: ⏐22.2-8.4⏐=13.8 > 9.266 1 and 2 are different. 2 and 3 are different.Notice that the results indicate that the mean of treatment 2 differs from the means of both treatments 1 and3, and that the means for treatments 1 and 3 are the same. Notice also that the Fisher LSD procedure (seethe computer output) gives the same results.(c) Use the graphical procedure in Section 3-5.3 to compare the treatment means. What conclusions can you draw? How do they compare with the conclusions from part (a).The scaled-t plot agrees with part (b). In this case, the large difference between the mean of treatment 2and the other two treatments is very obvious. S c a le d t D is t r ib u t io n (3 ) (1 ) (2 ) 5 10 15 20 25 T e n s ile S t r e n g t h(d) Construct a set of orthogonal contrasts, assuming that at the outset of the experiment you suspected the response time of circuit type 2 to be different from the other two. H 0 = µ1 − 2 µ 2 + µ3 = 0 H1 = µ1 − 2 µ 2 + µ3 ≠ 0 C1 = y1. − 2 y2. + y3. C1 = 54 − 2 (111) + 42 = −126 3-26

- 55. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY ( −126 ) 2 SSC1 = = 529.2 5 (6) 529.2 FC1 = = 31.31 16.9 Type 2 differs from the average of type 1 and type 3.(e) If you were a design engineer and you wished to minimize the response time, which circuit type would you select?Either type 1 or type 3 as they are not different from each other and have the lowest response time.(f) Analyze the residuals from this experiment. Are the basic analysis of variance assumptions satisfied?The normal probability plot has some points that do not lie along the line in the upper region. This mayindicate potential outliers in the data. Normal plot of residuals Residuals vs. Predicted 7.8 99 95 4.55 Norm al % probability 90 80 Res iduals 70 50 1.3 30 20 10 -1.95 5 1 -5.2 -5.2 -1.95 1.3 4.55 7.8 8.40 11.85 15.30 18.75 22.20 Res idual Predicted Residuals vs. Circuit Type 7.8 4.55 Res iduals 1.3 -1.95 -5.2 1 2 3 Circuit Type 3-27

- 56. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY3-17 The effective life of insulating fluids at an accelerated load of 35 kV is being studied. Test datahave been obtained for four types of fluids. The results were as follows: Fluid Type Life (in h) at 35 kV Load 1 17.6 18.9 16.3 17.4 20.1 21.6 2 16.9 15.3 18.6 17.1 19.5 20.3 3 21.4 23.6 19.4 18.5 20.5 22.3 4 19.3 21.1 16.9 17.5 18.3 19.8(a) Is there any indication that the fluids differ? Use α = 0.05.At α = 0.05 there are no difference, but at since the P-value is just slightly above 0.05, there is probably adifference in means.Design Expert Output Response: Life in in h ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 30.17 3 10.06 3.05 0.0525 not significant A 30.16 3 10.05 3.05 0.0525 Residual 65.99 20 3.30 Lack of Fit 0.000 0 Pure Error 65.99 20 3.30 Cor Total 96.16 23 The Model F-value of 3.05 implies there is a 5.25% chance that a "Model F-Value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) Estimated Standard Mean Error 1-1 18.65 0.74 2-2 17.95 0.74 3-3 20.95 0.74 4-4 18.82 0.74 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 0.70 1 1.05 0.67 0.5121 1 vs 3 -2.30 1 1.05 -2.19 0.0403 1 vs 4 -0.17 1 1.05 -0.16 0.8753 2 vs 3 -3.00 1 1.05 -2.86 0.0097 2 vs 4 -0.87 1 1.05 -0.83 0.4183 3 vs 4 2.13 1 1.05 2.03 0.0554(b) Which fluid would you select, given that the objective is long life?Treatment 3. The Fisher LSD procedure in the computer output indicates that the fluid 3 is different fromthe others, and it’s average life also exceeds the average lives of the other three fluids.(c) Analyze the residuals from this experiment. Are the basic analysis of variance assumptions satisfied? There is nothing unusual in the residual plots. 3-28

- 57. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Normal plot of residuals Residuals vs. Predicted 2.95 99 95 1.55 Norm al % probability 90 80 Res iduals 70 50 0.15 30 20 10 -1.25 5 1 -2.65 -2.65 -1.25 0.15 1.55 2.95 17.95 18.70 19.45 20.20 20.95 Res idual Predicted Residuals vs. Fluid Type 2.95 1.55 Res iduals 0.15 -1.25 -2.65 1 2 3 4 Fluid Type3-18 Four different designs for a digital computer circuit are being studied in order to compare theamount of noise present. The following data have been obtained: Circuit Design Noise Observed 1 19 20 19 30 8 2 80 61 73 56 80 3 47 26 25 35 50 4 95 46 83 78 97(a) Is the amount of noise present the same for all four designs? Use α = 0.05.No, at least one treatment mean is different.Design Expert Output Response: Noise ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] 3-29

- 58. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Sum of Mean F Source Squares DF Square Value Prob > F Model 12042.00 3 4014.00 21.78 < 0.0001 significant A 12042.00 3 4014.00 21.78 < 0.0001 Residual 2948.80 16 184.30 Lack of Fit 0.000 0 Pure Error 2948.80 16 184.30 Cor Total 14990.80 19 The Model F-value of 21.78 implies the model is significant. There is only a 0.01% chance that a "Model F-Value" this large could occur due to noise. Treatment Means (Adjusted, If Necessary) Estimated Standard Mean Error 1-1 19.20 6.07 2-2 70.00 6.07 3-3 36.60 6.07 4-4 79.80 6.07 Mean Standard t for H0 Treatment Difference DF Error Coeff=0 Prob > |t| 1 vs 2 -50.80 1 8.59 -5.92 < 0.0001 1 vs 3 -17.40 1 8.59 -2.03 0.0597 1 vs 4 -60.60 1 8.59 -7.06 < 0.0001 2 vs 3 33.40 1 8.59 3.89 0.0013 2 vs 4 -9.80 1 8.59 -1.14 0.2705 3 vs 4 -43.20 1 8.59 -5.03 0.0001(b) Analyze the residuals from this experiment. Are the basic analysis of variance assumptions satisfied? There is nothing too unusual about the residual plots, although there is a mild outlier present. Normal plot of residuals Residuals vs. Predicted 17.2 99 2 95 4.45 Norm al % probability 90 80 2 Res iduals 70 50 -8.3 30 20 10 -21.05 5 1 -33.8 -33.8 -21.05 -8.3 4.45 17.2 19.20 34.35 49.50 64.65 79.80 Res idual Predicted 3-30

- 59. Solutions from Montgomery, D. C. (2004) Design and Analysis of Experiments, Wiley, NY Residuals vs. Circuit Design 17.2 2 4.45 2 Res iduals -8.3 -21.05 -33.8 1 2 3 4 Circuit Des ign(c) Which circuit design would you select for use? Low noise is best.From the Design Expert Output, the Fisher LSD procedure comparing the difference in means identifiesType 1 as having lower noise than Types 2 and 4. Although the LSD procedure comparing Types 1 and 3has a P-value greater than 0.05, it is less than 0.10. Unless there are other reasons for choosing Type 3,Type 1 would be selected.3-19 Four chemists are asked to determine the percentage of methyl alcohol in a certain chemicalcompound. Each chemist makes three determinations, and the results are the following: Chemist Percentage of Methyl Alcohol 1 84.99 84.04 84.38 2 85.15 85.13 84.88 3 84.72 84.48 85.16 4 84.20 84.10 84.55(a) Do chemists differ significantly? Use α = 0.05.There is no significant difference at the 5% level, but chemists differ significantly at the 10% level.Design Expert Output Response: Methyl Alcohol in % ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 1.04 3 0.35 3.25 0.0813 not significant A 1.04 3 0.35 3.25 0.0813 Residual 0.86 8 0.11 Lack of Fit 0.000 0 Pure Error 0.86 8 0.11 Cor Total 1.90 11 The Model F-value of 3.25 implies there is a 8.13% chance that a "Model F-Value" this large could occur due to noise.Treatment Means (Adjusted, If Necessary) Estimated Standard 3-31